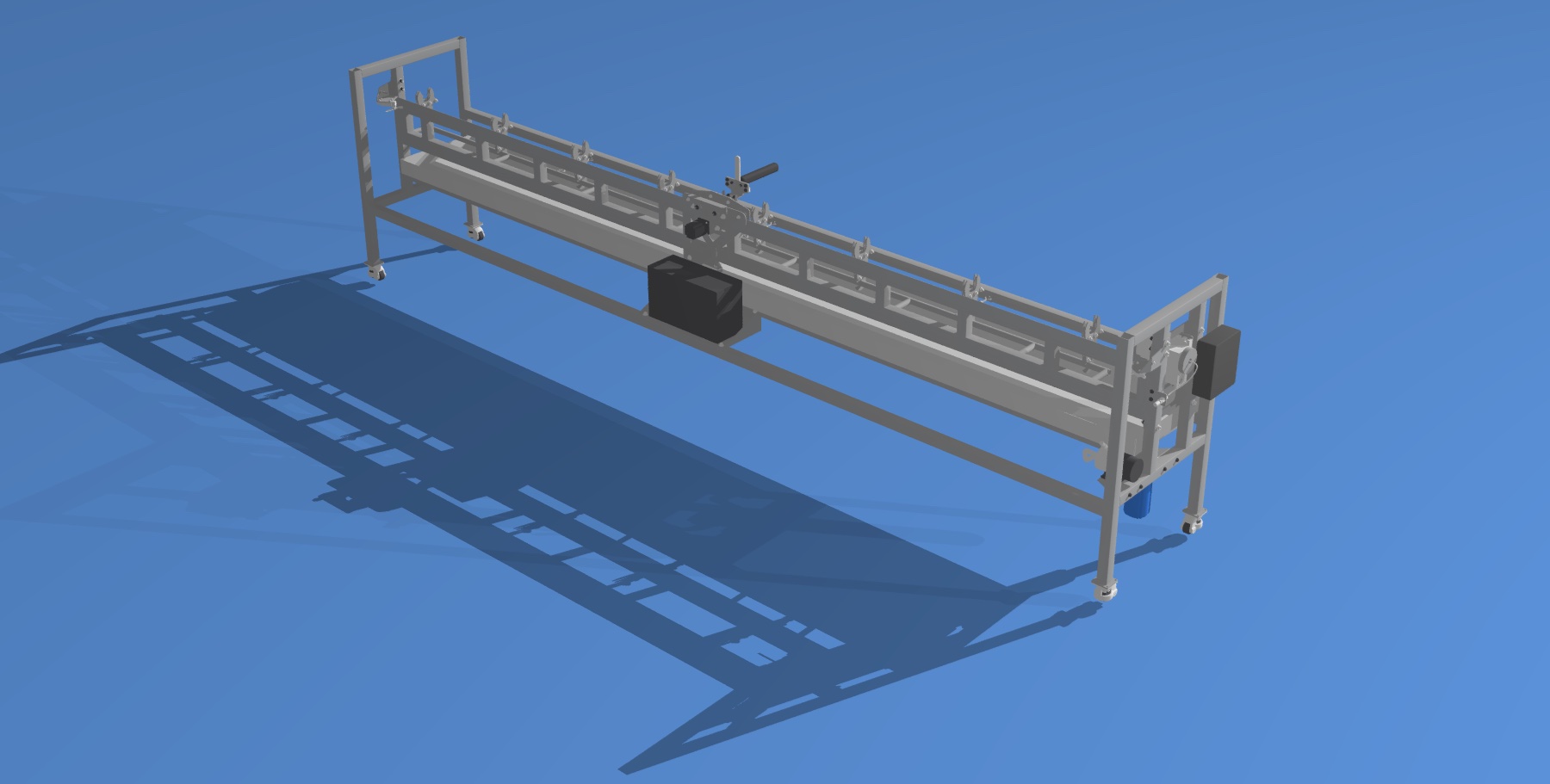

Update November 2025: A new production CNC Tube Notcher will be available for purchase early 2026.

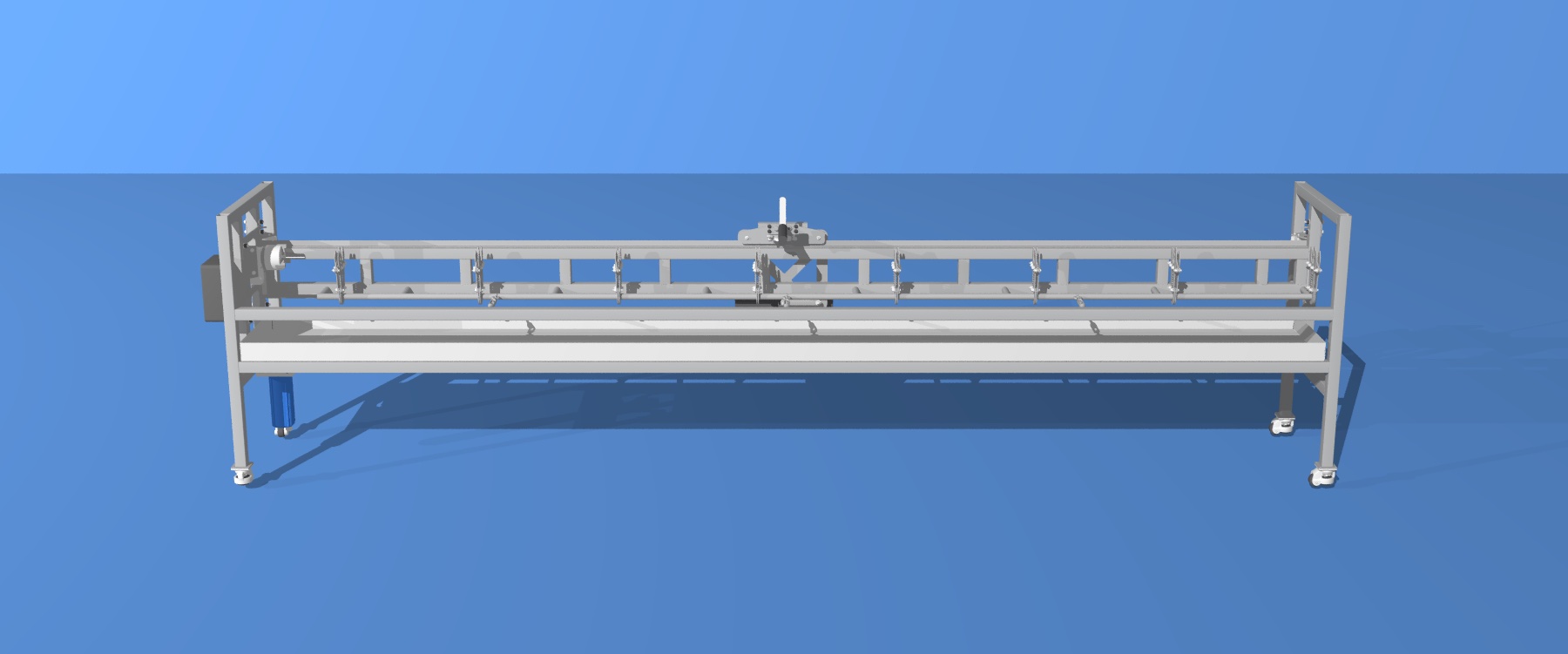

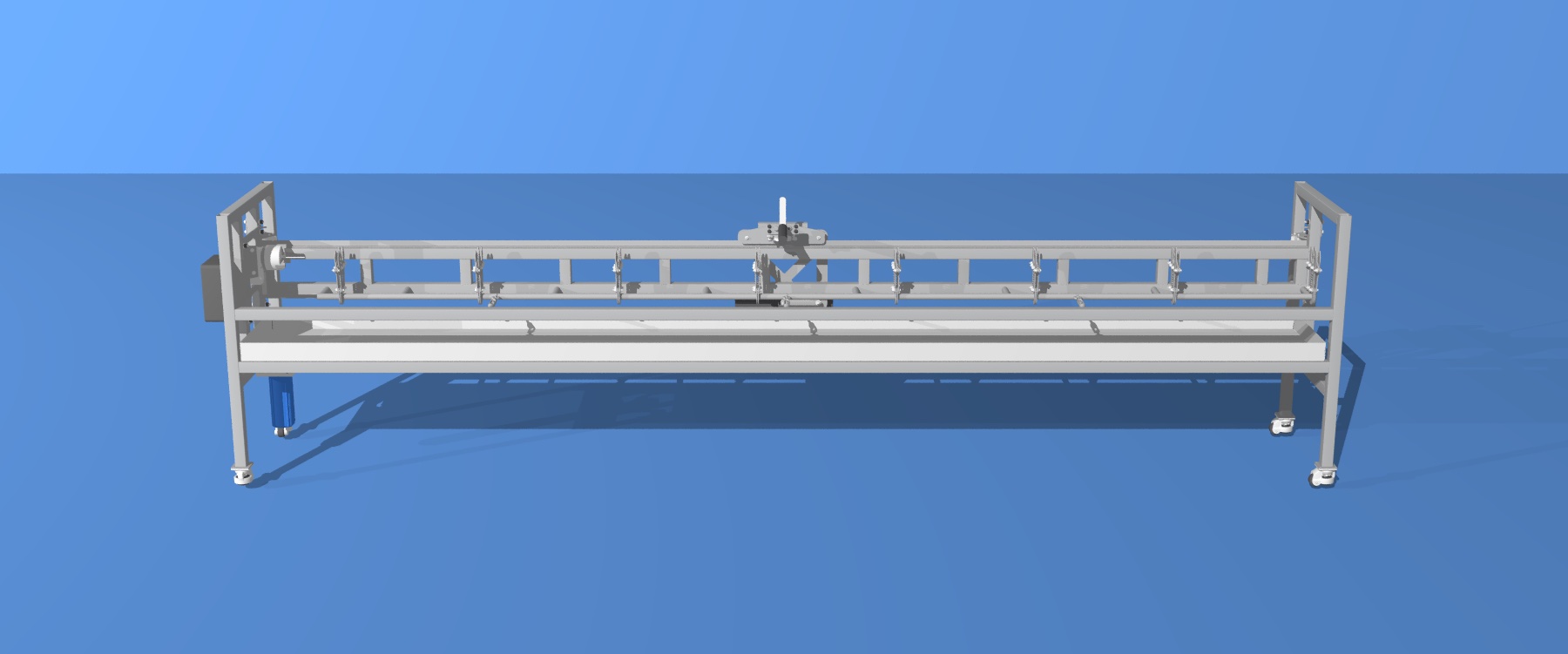

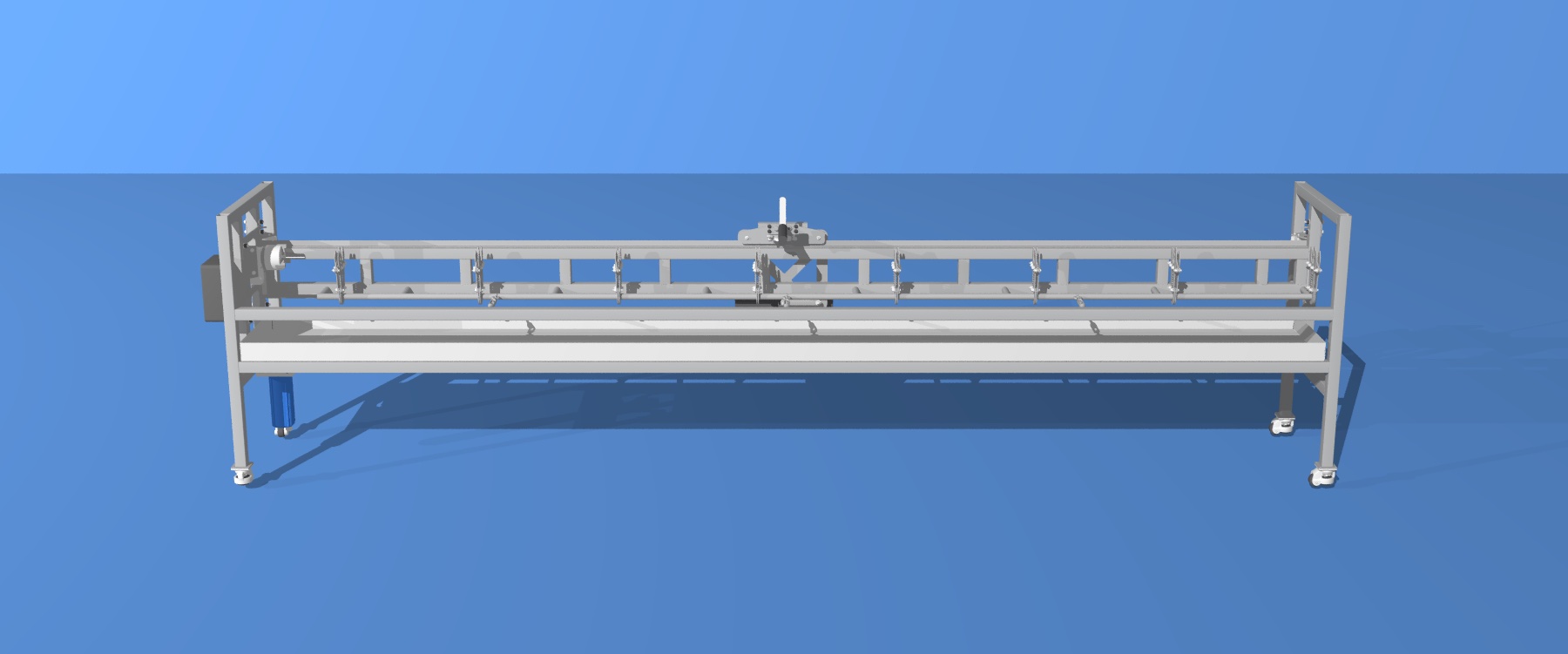

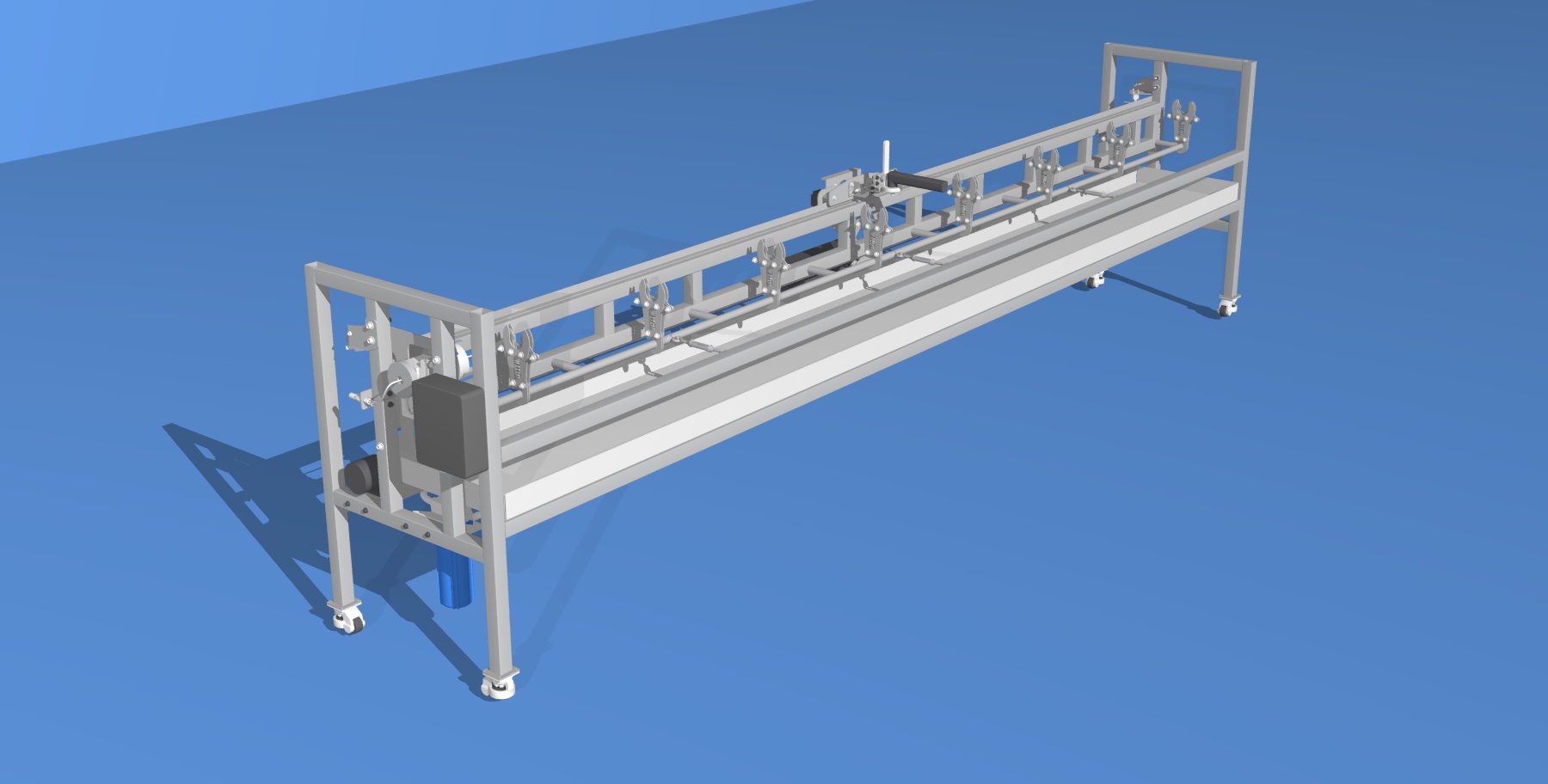

The Arma CNC Tube notcher automates cutting of metal tubing and pipe with coping for joints, tabs and slots for alignment and is compatible with the Arma Tube Bender complex bent tubing fabrication projects designed from CAD models.

The Arma Tube Notcher is ideal for fabricators building round tube structures such as vehicle chassis, roll cages, bumper cages, truck racks, etc.

The tube notcher supports the cutting of Steel and Aluminum round tubing and pipe with an outer diameter between 1” and 2”.

Wall thickness up to 3/8th inch is supported. Square tubing is not supported by this product.

Two axis positioning and cutting is supported. The torch cutter is always positioned perpendicular to the tube surface as the tube rotates and the torch travels along the length. This means that there may be a wedge shape that needs to be welded on coped joints especially for tubing with a thick wall.

The maximum supported length of tube and pipe is flexible as the length of the frame and rail can be customized during assembly. The reference notcher is 14’ wide supporting tubing with a maximum length of 12’. The notcher can be made smaller to accommodate confined workspaces and lengthened to cut full length tubes 24’ long.

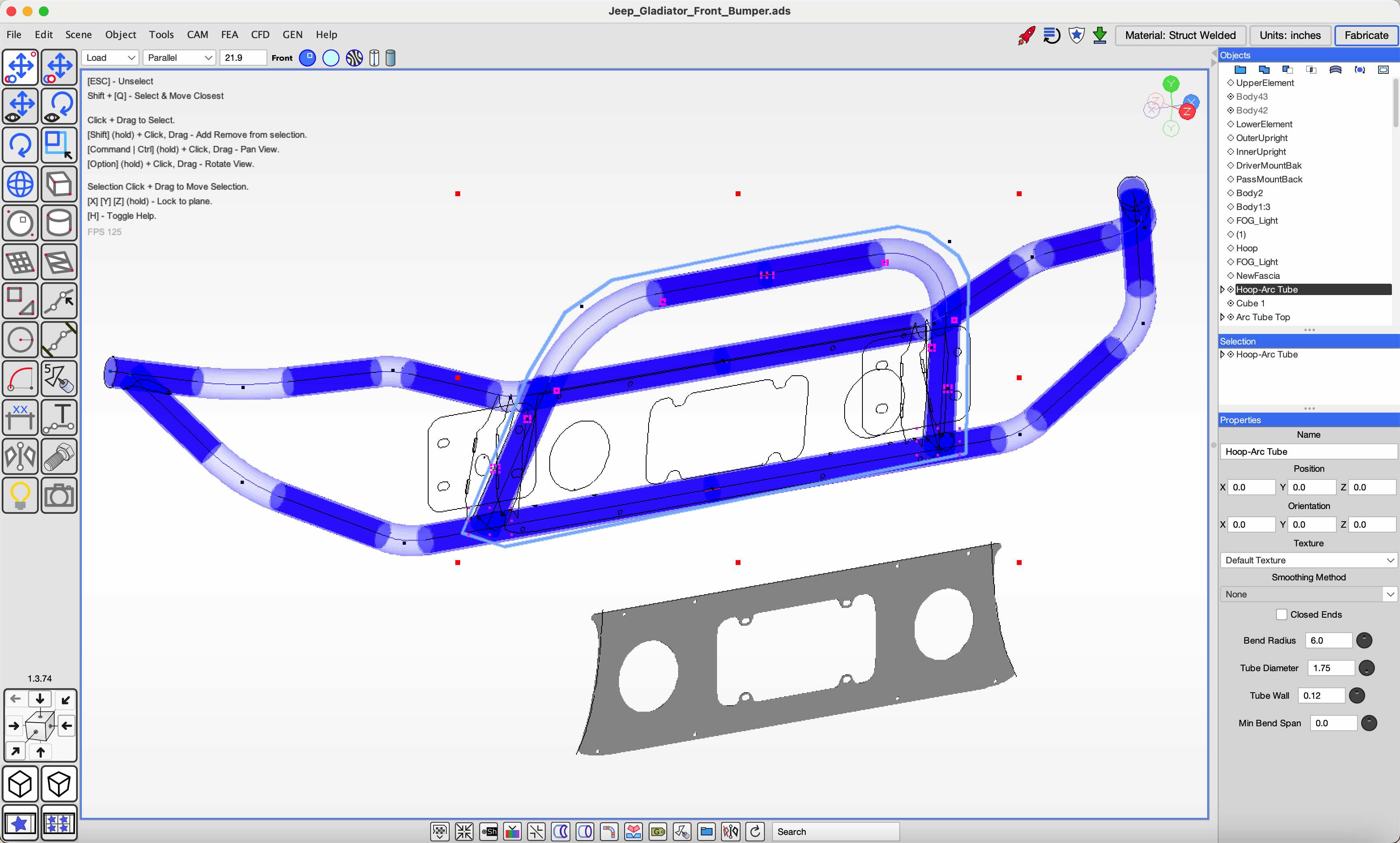

Control software in the Arma Design Studio application supports fabrication with new model designs or existing third parts cad models imported. Optionally a Mach3 compatible controller solution can be provided for customers wishing to use Mach3.

The Arma CNC Tube Notcher is intended to be an affordable automation tool for individual builders, medium sized business and industrial manufacturers.

Complex tube structures can be modelled in CAD software and fabricated in an efficient, accurate and repeatable manner.

Tube structures can be cut with coping edges for accurate fitment to connecting tube where it can be welded in place.

|

Cut precision coped joints on intersecting tubes with ease. Our system accurately cuts two or more intersecting joints so they fit together perfectly for welding. Tube coped joints can be automatically generated in our CAD/CAM software and easily modified for special cases. Notches can include multiple intersecting joints that don’t share the same centreline and may vary in diameter and wall thickness. The cutting torch maintains a fixed angle perpendicular to the tube—always cutting straight into it. As a result, joints use the tube’s outer profile on the acute (narrow) side and the inner profile on the obtuse (wide) side. This produces tight-fitting joints with no visible gaps, ensuring strong, clean welds. |

|

|

Tabs and slots can be automatically added to coped tube profiles in our CAD/CAM software. They ensure precise alignment when assembling your cut tubes, eliminating guesswork and reducing the need for external supports during welding. |

|

|

Cut tube end caps with integrated slots to securely fixture them in place during welding, ensuring clean, consistent results. |

|

|

Cut precise holes for weld-in bungs or slots for mating plates. Our CAD/CAM software can automatically generate plate profiles around tubes for tabs and attachments, and also supports fully custom cut shapes for specialized designs. |

|

|

Engrave labels, part numbers, material details, orientation marks, instructions, and more using the built-in engraving feature. |

|

|

Engrave or cut bend location markers to precisely position tubes in a bender for accurate manufacturing. Bend markers ensure each part is formed at the correct position along the tube length and rotation around its centre axis. With integrated bending and notching capabilities, even complex assemblies become straightforward. Our CAD/CAM software automatically compensates for radial growth to maintain exceptional accuracy. |

|

|

End-segment extensions with connecting tabs provide additional tube length for fixturing in benders while maintaining precise coped-end geometry. Many benders require a minimum straight length between the tube end and the bend, which can limit the ability to cut complex profiles directly. Tabbed extensions solve this by allowing complex notched ends to be plasma-cut in advance, then trimmed after bending with a small saw to expose the final coped joint. |

|

|

Route tubes around bends of any radius using our CAD/CAM software. The CNC plasma tube notcher can automatically cut pie wedges that are folded and welded to form smooth, custom bends. This method is ideal for fabricating exhaust systems, conduits, or tight-space routing where non-standard or variable bend radii are required. |

|

The Arma Design Studio CAD/CAM software can generate notch profiles for intersecting tubes with tabs in one part and corresponding slots in the connecting part. This aids in verifying alignment as tubes can only fit together in the correct location as well aiding in assembly where the tabs hold parts in place more easily resulting in less jig scaffolding for complex projects.

| ||||||||||||||